Part 5: Purchasing and Ordering--Procedures and Practices

Purchasing and Ordering

What exactly is the difference? Purchasing is setting the policy on which suppliers, brands, grades and varieties of products will be ordered. These are your standardized purchase specifications; the specifics of how items are delivered, paid for and returned. These specifications are negotiated between management and distributors. Basically, purchasing is what you order and from whom. Ordering, then, is simply the act of contacting the suppliers and notifying them of the quantity you require. This is a simpler, lower-level task. Here are the basics:

- Develop a purchasing program. Once menus have been created that meet your customers' satisfaction and your profit needs, develop a purchasing program that ensures your profit margins.

- An efficient purchasing program incorporates: Standard purchase specifications based on standardized recipes, and standardized yields and portion control that allow for accurate costs based on portions actually served.

- Keep in mind: Purchasing more than you need usually results in poor portioning, excess spoilage, waste and theft. Not buying enough can mean paying retail prices, or using a more expensive substitute.

- Purchasing procedures. These procedures should include creating written purchasing specifications for every product and selecting good, reliable purveyors. Your purchasing procedures should do three things:

- Allow you to purchase the required items at prices that meet your food cost goals.

- Maintain control over your existing inventory.

- Establish a set of procedures to be sure that you receive quality product at the best price.

- Purchasing responsibility. Either take on the purchasing yourself or assign a specific employee to do it. Make sure that this person keeps current with ever-changing food prices.

- Price checks for different vendors. Sometimes you may find that one vendor is less expensive than another for a while, and then this may shift. Keep current with competing vendors' prices.

Purchasing Specifications

By creating purchasing specifications, you can control which items you purchase and you can maintain product consistency. This information is extremely important if you have more than one person that does ordering in your operation. You need to record the following basic information:

- Purchasing specifications. They state the exact requirements for the amount and quality of items purchased. These specifications should include:

-

- Product name

- Quantity to be purchased (designated with correct unit such as pounds, can size, etc.)

- Indication of grade, if applicable

- Unit by which prices are quoted

- What the product will be used to produce

- Meats. Meats should be inspected by the USDA or

other appropriate agency. The parts or packaging

should carry a federal or state inspection stamp.

- Eggs. Eggs should have a USDA grade; frozen and

dried eggs should be pasteurized.

- Shellfish. Shellfish should be purchased from

suppliers that appear on public health service Food

and Drug Administration lists of Certified Shellfish

Shippers or on lists of state-approved sources. The

control tags must be available if live shellfish are

used.

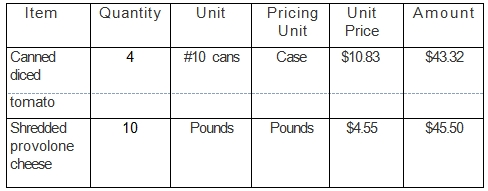

- Introduce a record sheet. Make it readily available for all your employees. They need to be sure that they're ordering the correct items in the correct amounts. You're also more likely to attain your desired food cost by keeping these records and maintaining purchasing controls. Keeping your food cost down will help you to maximize profits from your menu prices. The following form illustrates an example of a purchasing specification form:

This article is an excerpt from the Food Service Professional Guide to Controlling Restaurant & Food Service Food Costs, authored by Douglas R. Brown, published by Atlantic Publishing Company. This excerpt has been reprinted with permission of the publisher. To purchase this book go to: