Part 2: Perpetual Inventory

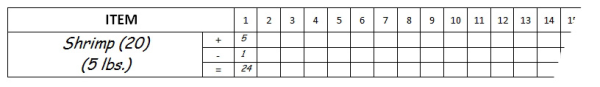

The perpetual inventory is a check on the daily usage of your main entree items from the freezers and walk-ins. This is for tracking expensive items, such as meat, seafood, chicken, cans of caviar, etc. When completed, the perpetual inventory will ensure that no bulk products have been pilfered from the freezer or walk- ins. Computer software programs and some POS systems will track this information for you. The following is an example of a Perpetual Order Form:

- List all the food items that are listed on the Sign-out Sheet and Yield Form. In the "Size" column, list the unit size in which the item is packaged. The contents of most cases of food are packed in units such as 5-pound boxes or 2-pound bags. Meat is usually packed by the number of pieces in a case and the case's weight. The size listed on the perpetual inventory must correspond to the size the preparation cooks are signing out of the freezer and walk-ins.

- In the "Item" column, enter the number of each item listed. For example, if shrimp is packed in 5-pound boxes and you have two 50-pound cases, there are 20 boxes. Enter 20 in the "Item" column. Each number along the top corresponds to each day of the month. At the end of each day, count all the items on hand and enter this figure on the "=" line. Compare this figure to the "Amount Ordered or Defrosted" column on the Preparation Sheet; these amounts must be the same as the total number of each item on the "-" line. If there were any deliveries, place this total on the "+" line.

- Theft. Theft can occur when someone removes a box of shrimp from the case, for example. The person then reseals the case with the other boxes to hide the gap.

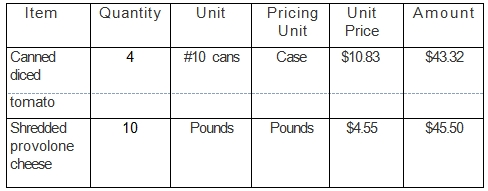

- Check the invoices every day for the items delivered that are in your perpetual inventory. Ensure that all items signed off as being delivered are actually in the storage areas. Should there be a discrepancy, check with the employee that signed the invoice. The number of items you start with (20) plus the number you received in deliveries (5), minus the amount signed out by the preparation cooks (1), must equal the number on hand (24). If there is a discrepancy, you may have a thief.

- What to do if you suspect theft. Should you suspect a theft in the restaurant, record the names of all employees who worked that particular day. If thefts continue to occur, a pattern may develop among the employees who were working on all the days in question. Compute the perpetual inventory or other controls you are having a problem with at different times of the day and before and after each shift. This will pinpoint the area and shift in which the theft is occurring. Sometimes, placing a notice to all employees that you are aware of a theft problem in the restaurant will resolve the problem. Make it clear that any employee caught stealing will be terminated.

Purchasing Kickbacks and Gifts

Unfortunately, the food service industry is notorious for kickbacks. It is even more unfortunate that these kickbacks or gifts are essentially paid for by you in the form of higher prices. Here are some ideas to help keep kickbacks out of your store:

- Purchasing and receiving must be done by different employees. The person ordering should not be the same person receiving and checking the items.

- Kickback policy. Develop a general policy and list it in your employee handbook that employees cannot receive anything for free from a vendor or potential vendor.

- Change positions. People become complacent over time; move positions around.

- Check on prices of expensive items like meat and seafood yourself.

The purchasing department is the linchpin when it comes to reducing costs. It is much easier to control costs in this area than anywhere else in the operation. The bottom line is that astute buying techniques offer the best opportunity for a business to increase its overall profits.

The purchasing department is the linchpin when it comes to reducing costs. It is much easier to control costs in this area than anywhere else in the operation. The bottom line is that astute buying techniques offer the best opportunity for a business to increase its overall profits. As a purchasing manager, it is important to set standards. Decide up front exactly what types of drinks you need to purchase and the conditions under which you will place an order. These are your purchase specifications.

As a purchasing manager, it is important to set standards. Decide up front exactly what types of drinks you need to purchase and the conditions under which you will place an order. These are your purchase specifications. This area of purchasing offers a great scope for cost reductions. Unfortunately, it is often neglected. Do so at your peril! Many well-devised purchasing plans fall at this last hurdle. Don't marginalize this important procedure.

This area of purchasing offers a great scope for cost reductions. Unfortunately, it is often neglected. Do so at your peril! Many well-devised purchasing plans fall at this last hurdle. Don't marginalize this important procedure.