By Douglas R. BrownAtlantic Publishing

By Douglas R. BrownAtlantic Publishing

Goals

The goals of receiving are to ensure foods are fresh and JL safe when they enter your facility and you are receiving what you ordered and are paying for. Transfer items to proper storage as quickly as possible.

Let’s look more closely at two important parts of receiving:

- Getting ready to receive food.

- Inspecting the food when the delivery truck arrives.

Receiving Policy

Receiving Tips

There are several important guidelines to keep in mind and tasks to complete as you get ready to receive food:

- Calibration. Make sure all scales and thermometers are in place and calibrated.

- Sanitary carts. Make sure your receiving area is equipped with sanitary carts for transporting goods.

- Plan ahead for deliveries to ensure sufficient refrigerator and freezer space.

- Mark all items for storage with the date of arrival or the "use by" date.

- Lighting. Keep the receiving area well lit and clean to discourage pests.

- Remove empty containers and packing materials immediately to a separate trash area.

- Keep all flooring clean of food particles and debris.

- Delivery truck. When the delivery truck arrives, make sure it looks and smells clean and is equipped with the proper food-storage equipment. Then inspect foods immediately.

- Check expiration dates of milk, eggs and other perishablegoods. Make sure shelf-life dates have not

expired.

- Frozen foods. Make sure frozen foods are in airtight, moisture-proof wrappings.

- Reject foods that have been thawed and refrozen. Look for signs of thawing and refreezing, such as large crystals, solid areas of ice or excessive ice in containers.

- Rejecting canned goods. Reject cans that have any of the following: swollen sides or ends; flawed seals or seams; dents; or rust. Also reject any cans whose contents are foamy or smell bad.

- Check the temperature of refrigerated and frozen foods, especially eggs and dairy products, fresh meat and fish and poultry products.

- Look for content damage and insect infestations.

- Rejecting dairy products. Reject dairy, bakery and other foods delivered in flats or crates that are dirty.

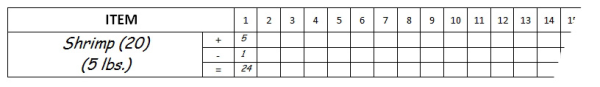

- Weighing items. Meats, fish and most items ordered by the pound must be weighed and tagged. Food items purchased by count need to be checked and counted. All items received must be counted, weighed and date stamped. Don't deviate from this critical step.

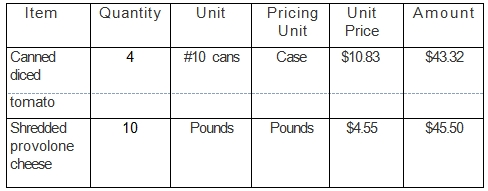

- Invoice accuracy. Check the accuracy of the invoice with regard to the purchase order, specifically price, damage, quality, quantity, brands, grades and variety. Items that are not correct need to be noted and returned before the driver leaves and the driver must sign the form. The vendor's invoice also should be checked against the actual purchase order.

- Don't let delivery people into your storage areas.

- Items packed in ice. These items need to be removed from the ice prior to weighing.

- Check animal cavities in fish and poultry for ice.

- Delivery personnel should be friendly, not rushed, and professional, but not too friendly. Ensure they know that it doesn't matter if they are in a rush; you are going to check everything in and count and weigh everything prior to their leaving.

- All food products must be date coded, rotated and put away immediately.

- Placed in order. Products should be placed on the shelves in the same order as the inventory sheets and purchase order forms. This will help in inventory counting and control.

- Determine which employees are allowed to access the storage areas. Storage areas are prime targets for theft. Not only employee theft, but if areas aren't kept locked and secure, outside people will be able to get in and help themselves to your products.

- Garbage can liners. In the kitchen, consider using clear trash bag liners as another method to deter pilferage.

- Keep your back door locked, well lit and on an alarm system. A small viewing panel or glass with a wire-enforced panel will enable the receiving employee to see who is at the back door.

By Douglas R. Brown

By Douglas R. Brown

By Douglas R. Brown

By Douglas R. Brown