Social Media is not a fad and will be the way people get messages across now, and even more so in the future.

Social Media is not a fad and will be the way people get messages across now, and even more so in the future.

The question is it right for everyone and every Bar. Maintaining a page is much more time consuming than one might think. If a page is not updated regularly it can harm your business more than help.

The questions you should ask yourself if you intend on opening up a Facebook or Twitter page is Why? Who? and how?

Why: Why are you starting a page. Your answer should not be because everyone else is doing it. You should take your time and figure out why you actually want a page and why will your page and business is different than all the others that are out there.

Who: Who will your page target. Is it existing clients, potential new clients. Your local neighborhood, the city at large. This will give you an idea of the type of content you should be posting on a weekly, daily basis.

How: How will you reach your taget market? Is it with promotions, weekly specials, open mic night, live bands. Its important that your page lets people inside your business and is the place where one will go to get information on what is happing there at any given time.

In the end jumping into social media is something one should embrace and treat as a new way to reach a larger scale of people for free or for minimal costs. Although do not just jump in blindly. Get yourself a plan and go from there I know you may just want to rush into it, but take your time try different things till you get it right. Once you do, and if you have a unique strategy you will be shocked at how people will respond.

There are countless reasons why one should be on top of their liquor inventory. Being in the business now for over 10 years here are the 4 most prominent points I have seen during that time.

There are countless reasons why one should be on top of their liquor inventory. Being in the business now for over 10 years here are the 4 most prominent points I have seen during that time. Social Media is not a fad and will be the way people get messages across now, and even more so in the future.

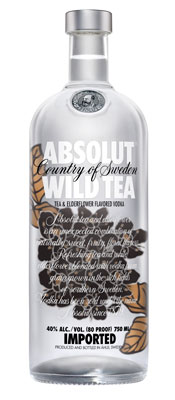

Social Media is not a fad and will be the way people get messages across now, and even more so in the future. With all the new Brands and flavors of alcohol and liquor coming out every day. We share with you The Shelf brought to you by our friends at

With all the new Brands and flavors of alcohol and liquor coming out every day. We share with you The Shelf brought to you by our friends at  In any business you always need to manage your day to day properly, but one thing you always need to consider and always work on is staying current with the latest and upcoming trends.

In any business you always need to manage your day to day properly, but one thing you always need to consider and always work on is staying current with the latest and upcoming trends. Scannabar recently had the pleasure of exhibiting our liquor, beer and wine inventory software at the Florida Restaurant Association show in Orlando, Florida, September 12th to the 14th. Contrary to other years, it is quite apparent that the economy is slowly coming back to where it was, this displayed by the volume of people that attended and the steady flow of hospitality operators we had the opportunity to discuss our cost saving solution with. It is also quite evident that operators are looking for solutions that will help them save both time and most importantly money in respect to their most valued liquid assets.

Scannabar recently had the pleasure of exhibiting our liquor, beer and wine inventory software at the Florida Restaurant Association show in Orlando, Florida, September 12th to the 14th. Contrary to other years, it is quite apparent that the economy is slowly coming back to where it was, this displayed by the volume of people that attended and the steady flow of hospitality operators we had the opportunity to discuss our cost saving solution with. It is also quite evident that operators are looking for solutions that will help them save both time and most importantly money in respect to their most valued liquid assets.

Becoming a Bartender

Becoming a Bartender Many hospitality operators want to know what their liquor cost is. Many times, we simply divide the cost of goods sold by the revenues to come up with a liquor cost percentage. Often, this number is inaccurate or to late in the cycle to take corrective actions.

Many hospitality operators want to know what their liquor cost is. Many times, we simply divide the cost of goods sold by the revenues to come up with a liquor cost percentage. Often, this number is inaccurate or to late in the cycle to take corrective actions.